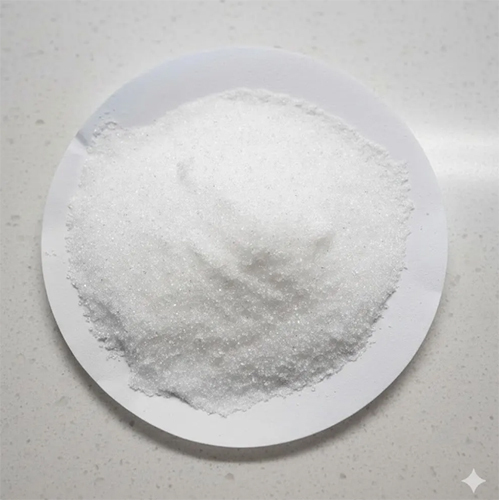

Brucite Powder

Price 80 INR/ Kilograms

Brucite Powder Specification

- Form

- Powder

- Solubility

- Insoluble in water, soluble in acids

- Purity

- 99 %

- Storage

- Room Temperature

- Ph Level

- 8-9

- Grade

- Industrial Grade

- Type

- Brucite Powder

- Usage

- Filler, Coating additive

- Application

- Industrial

Brucite Powder Trade Information

- Minimum Order Quantity

- 250 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

About Brucite Powder

Special Features and Exceptional Use of Brucite Powder

Brucite Powder stands out for its high industrial grade, lofty purity, and reliable performance as a coating additive and filler. Its superior pH balance makes it suitable for various applications where stability is paramount. Additional features include effortless solubility in acids and an insoluble nature in water, making it ideal for specific industrial processes that demand integrity under diverse conditions. Choose this top-rated powder for solutions that require both consistency and functional versatility.

Main Export Markets, Payment, and Packaging for Brucite Powder

Brucite Powder enjoys a premium presence in global export markets, with dependable transportation to Europe, Southeast Asia, and the Middle East. Flexible payment terms cater to international transaction needs, while sale prices remain competitive for buyers looking for quality and affordability. Packaging details are tailored for protection and longevity, ensuring the product arrives safely and maintains its superior traits, enabling seamless integration into industrial processes without concerns about degradation.

FAQ's of Brucite Powder:

Q: How should Brucite Powder be stored for optimal performance?

A: Brucite Powder should be stored at room temperature in a dry environment to maintain its superior quality and ensure consistency in all applications.Q: What are the primary uses of Brucite Powder in industrial settings?

A: Brucite Powder is mainly used as a filler and coating additive in various industrial applications. Its unique chemical properties and high purity ensure excellent performance in diverse manufacturing processes.Q: When is the best time to integrate Brucite Powder into manufacturing processes?

A: Brucite Powder can be introduced during the formulation or blending stage, depending on the specific requirements of the coating or filler application.Q: Where is Brucite Powder most commonly exported?

A: Brucite Powder is predominantly exported to Europe, Southeast Asia, and the Middle East, serving a wide range of industrial sectors in these regions.Q: What are the benefits of using high-purity Brucite Powder?

A: Using 99% pure Brucite Powder ensures minimal impurities, offering enhanced stability, improved product performance, and compatibility with various industrial applications.Q: How is Brucite Powder packaged for international transportation?

A: The powder is securely packaged to prevent contamination or moisture exposure, maintaining its premium quality during transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chemical Category

Baytes Powder

Minimum Order Quantity : 100 Kilograms

Type : Inorganic Sulfate Mineral

Grade : Industrial Grade

Usage : Filler, Extender, Weighting Agent, Additive

Flamex Fire Retardant Additives

Price 240 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Flamex Fire Retardant Additives

Grade : Industrial Grade

Usage : Filter aid, Abrasive, Insulation

Purity : 99 %

Barium Sulphate PPT

Price 18 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Type : Barium Sulphate PPT

Grade : Industrial Grade

Usage : Cleaning agent, pH adjustment

Purity : 99 %

Zinc Borate

Minimum Order Quantity : 100 Kilograms

Type : Hydrated Zinc Borate (most common grade)

Grade : Industrial Grade

Usage : Flame retardant, smoke suppressant, corrosion inhibitor, polymer additive

Send Inquiry

Send Inquiry